TXCube, your industrial design company

TXCube is the partner of choice to support all innovative companies to achieve their objectives of product design at target cost, requiring the implementation of multiple «know-how».

We support companies of all sizes from start-ups to large publicly traded companies, in the phases of design, qualification, industrialization and manufacture of their products. We also manage the impact of product design enhancements on its manufacturing throughout its life cycle.

Industrial design office

TXCube provides this industrial product design and manufacturing know-how from the genesis of a product to the end of its life thanks to its team of experienced project managers and the support of its mechanical design office, electronic design office and software development office.

What distinguishes us from traditional industrial design offices is that we do not stop at product design because we only select projects that are intended to be industrialized and manufactured by our company and in which we can apply all our industrial design services. Our teams always keep in mind a design for manufacturing and assembly. We will pay particular attention to the choice of components (by validating their availability for example, their possible withdrawal from the market), the feasibility study of injected parts molds, the way in which we will be able to assemble the product (ease, need for tooling, choice of assembly solutions and associated time), the testability of its functionalities and characteristics in production and other points such as quality controls, packaging, traceability and transport constraints.

Advice and industrial design services for a successful project

We also provide our clients with product design engineering services if necessary (drafting specifications, functional advice, feedback, eco-design, risk analysis, mock-ups and prototypes, regulatory analysis), and downstream services with all phases of industrialization and production of prototypes, preproduction and mass production, certifications, complete development of test benches, packaging and traceability as well as optimization of logistics aspects.

We know how to act in all phases of a customer project, including a product already in production to optimize quality, costs and deadlines. We will be able to advise you to redesign your product and achieve your industrial objectives.

Industrial project management

Our industrial design house is composed of experienced project managers able to master all these phases of product design and manufacturing, identifying project risks at each stage, to anticipate issues and get a synthetic vision of the project and its planning. They all have previous experience in the design of complex systems combining the fields of mechanics, electronics or embedded software.

The industrial project manager leads the various internal and external stakeholders and ensures the weekly relationship with the customer.

As a key figure in the success of the project, he ensures that the QCD objectives (Quality, Costs, Deadlines) are met by anticipating risks and implementing the means to reduce those risks.

It ensures the overall consistency of the customer’s requirements and puts in place the means to ensure the required quality level, the monitoring of the non-recurring engineering costs (NRE), the volume cost of the product and the deadlines with a schedule updated regularly.

Where does the collaboration with TXCube start?

TXCube starts throughout the design phases of industrial products, and can participate in:

- The validation of an innovative concept from the mock-up phase (often called POC: « Proof of concept »). It also supports an initial economic analysis and highlights the technical risks. We then draft specifications to allow the mechanical design office and the electronic design office to start designing the product.

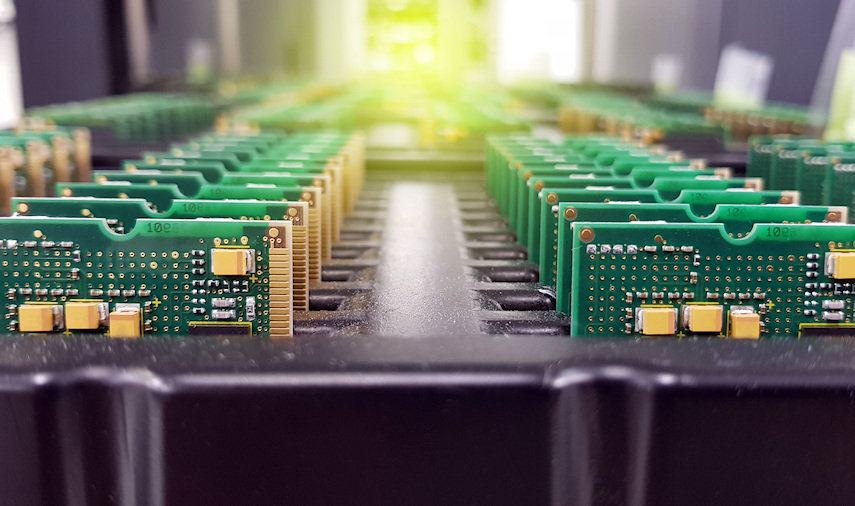

- The first prototypes of electronic, mechanical and finished goods assembled and tested, as well as the packaging.

Manufacturing and assembly

For some projects, our industrial design office only intervenes after the prototype phase done in-house by the customer. Therefore, we just focus on the industrial solutions of the products and the development of the associated manufacturing equipment.

The pre-series phase then allows to qualify the production and test equipment, with limited production volumes, but sufficient to validate the equipment statistically. This phase is vital to correct youth problems, whether related to the design, manufacture or use of end customers. It makes it possible to finalise internal qualifications and certifications, to develop production tests and to optimise logistics aspects.

Got a project ?

TXCube brings the experience on the best way to meet your challenges. So, don’t wait and