Pre-production during the project

The pre-production phase takes place just before mass production.

Pre-production is a key step in the development of a project. This initial production is a preamble to mass production. It helps to complete design validation and product qualification. It must not be underestimated to avoid discovering issues at mass production phase.

Pre-production manufacturing: a critical phase

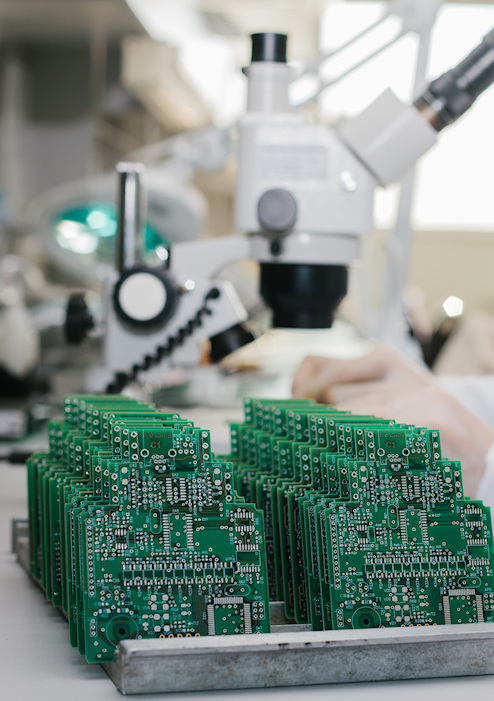

Pre-production occurs after the product industrialization and the approval of prototypes. The final manufacturing tooling for parts such as plastic injection molds and electronic boards (PCBAs) are ready and available at this stage. The final components on the bill of materials have been selected and functionally validated during the first prototype phases (POC, EVT, DVT).

The pre-production stage consists of manufacturing a few hundred units (mostly between 100 and 200 products) in order to approve the technical means for mass production (repeatability of assembly tools, testers, etc.), to feed the “field tests” confirming the correct use and performance of the products and the completion of the product certification phase.

Validation of the production equipments

The first goal of pre-production is to approve the tooling for the assembly line and to guarantee the product conformity with the customer specification requirements.

These tooling can be defined as follows:

-

- Assembly tooling (mounting templates, assembly tools, etc).

- Testers (functional, VRT, burn-in, etc).

- Specific test benches (sealing, impact, keyboard keys, etc).

During the pre-production step, the results of each industrial equipment are analyzed in detail with a projection towards mass production.

Pre-series are a validation phase of mass production.

Field Test

Pre-production must also allow the customer to validate the products under current conditions of use in the field. We call that phase “Field tests”. Pre-series products must be tested under all possible conditions of use and by several different users.

All remarks must be noticed and shared, and the validation of this pre-production phase triggers the start of the mass production phase. The validated pre-series products are retained as “Golden Samples”.

Preparation of certifications

Pre-production is also used to achieve product certifications for all countries in which the products will be marketed. The list of countries is provided by our customers.

The certifying laboratories require products issued from the serial production equipment to carry out the tests and perform the final certifications. They are therefore taken on the pre-series even if some pre-certification tests have been carried out on the prototypes. All tests are repeated on products from the pre-series. It should be noted that some tests carried out by laboratories on products are destructive tests. A sufficient number of pre-production units must therefore be provided for.

Got a project ?

TXCube brings the experience on the best way to meet your challenges. So, don’t wait and